HU-106A Automatic Pressurized Strapping Machine

HU-106A automatic pressurized strapping machine is specially designed for the bulking of the bulky items, and the pneumatic force can be customized according to the user.

E-mail:[email protected]

HU-106A automatic pressurized strapping machine is specially designed for the bulking of the bulky items, and the pneumatic force can be customized according to the user.

HU-106A Automatic Pressurized Strapping Machine Technical Parameters:

Voltage/ power: 380V/50HZ 750W/5A

Air source: 4-8kg/cm 2

Packing speed: ≤7 seconds / channel (adjustable)

Table height: 450-750mm (can be customized according to user's needs)

Frame size: 800mm wide* height as required

Bundling form: 1 or more parallel, the way is a little moving, manual hit, foot switch

Applicable bag: Thick (0.55~1.2)mm*Width (9~15)mm

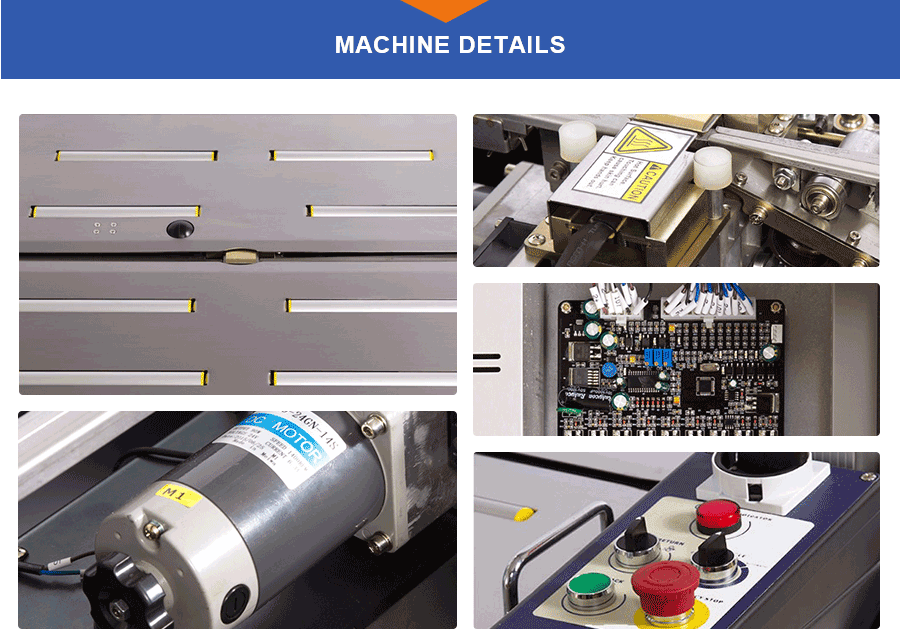

Electrical configuration: LG "PLC" control, French "TE" Japan "OMRON", "ZIK" electrical appliances.

HU-106A automatic pressurized strapping machine adopts "LG" PLC control, and the purchased electrical components are world famous products like Japanese "OMRON", French "TE", Taiwan "MCN" and photoelectric switch control. The mechanical design quotes Japanese technology, which has reasonable design, coordinated action, and high reliability. It has three functions to choose manual, automatic, and continuous controlling. It is easy to use, fast, can be suitable for high-speed production flow operation, aluminum alloy bracket, maintenance-free maintenance. This machine has a wide application range in the chemical fiber industry, tobacco re-baking enterprise, pharmaceutical industry, publishing industry, refrigeration and air-conditioning industry, home appliance industry, ceramic industry, and fire industry.

HU-106A automatic pressurized strapping machine working principle: the packaged object is basically processed in the middle of the machine. First, the right abutment rises, the front end of the belt is pressed, the strap is tightened and tied on the object, then the left acrosome is raised, and the appropriate position of the lower belt is pressed, and the heating sheet is heated. Stretch into the middle of the two belts, the middle top knife rises, cut the belt, and finally put the next strap to the position to complete a work cycle.

-

HU-2300A Spiral Arm Automatic Film Wrappin

-

HU-2000C Pressurized Automatic Film Wrappi

-

HU-2000A Automatic Stretch Film Wrapping M

-

HU-1000A Automatic Pallet Wrapping Machine

-

HU-105B Automatic Wear-sword Packing Machi

-

HU-106A Automatic Pressurized Strapping Ma

-

HU-105A Horizontal Type Automatic Strappin

-

HU-104A Automatic Strapping Machine

- Tel:+86-371-86151927

- Phone:+86-17803888506

- E-mail:[email protected]

- Skype:Magret Han

- Address:NO.1 CUIZHU STREET, NATIONAL HIGH NEW ZONE, ZHENGZHOU, CHINA

- Online Consultation

- Packaging Machine Series

- Sauce Packaging Machine

- Vacuum Packaging Machine

- Pillow Packaging Machine

- Powder Quantitative Packaging Machine

- Filling Machine Series

- Sauce Filling Machine

- Weighing Filling Machine

- Sealing Machine

- Vacuum Sealing Machine

- Filling and Sealing Machine

- Strapping Machine

- Labeling Machine

- Coding Machine

- Jet Printing Machine

- Shrinking Machine

- Capping Machine

- Carton Unpacking & Sealing Machine

- Production Line

- 5-50kg weighing filling & packing machine